From 2022 to 2027, the indoor vertical farming industry is projected to grow six-fold to a market size of more than $17 billion.

Benefits of vertical farming

Diverse food crops can be grown vertically in indoor facilities and greenhouses.

Vertical farming allows food production facilities to be built close to population centers, rather than only in fields or greenhouses in rural areas. RII partner Vertical Harvest Farms (VHF) grows food year-round, which is especially important in places with short growing seasons. By locating operations in remote population centers, consumers can purchase food without the carbon associated with cross-country transit.

Can vertical farms feed the world?

Can vertical farms feed the world?

VHF (Jackson Hole, Wyoming) also grows the futures of its community and staff. The group operates using an inclusive employment model, with an integrated mix of traditional employees and employees with intellectual and/or physical disabilities.

By stacking crops in vertical tiers, VHF’s Wyoming facility triples the growing space of their 0.1-acre building footprint. In their future Maine facility, the growing space will be over nine times larger than their 0.5-acre facility.

Maximizing yield

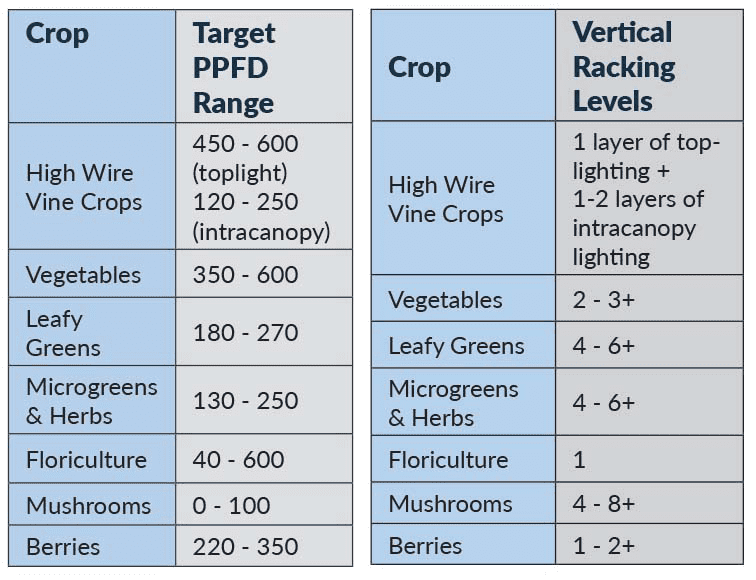

Vertical farms achieve target yields by maximizing crop canopy area and number of vertical tiers. Consider the number of tiers cultivation spaces can accommodate, given crop type, plant stages of growth, and lighting system mounting height. Some CEA producers cultivate vegetables and herbs in racking systems of over twenty tiers. Engage vertical racking partners during design to plan for 8- to 12-week lead times for delivery.

VHF has used their indoor Wyoming facility to trial many factors to maximize yield, including crop-specific growing and harvesting techniques like optimal lighting and rack density, climate controls and crop transport automation. VHF’s newest facility in Portland, Maine, will leverage that research to produce over 2 million pounds of local fresh greens annually.

Considerations for resource efficiency

Water efficiency can be a major benefit of vertical indoor cultivation approaches.

VHF views its business holistically, designing operations to work at the intersection of climate resilience, food access and economic inclusivity. By utilizing hydroponic growing methods that reduce water demand from their crops and recirculate the water in the system, their crops are grown with less than 10% of the water of field-grown crops.

While water use can be lower, energy demand for indoor vertical farms can be higher than other cultivation approaches. Reducing energy consumption from lighting systems can be an effective way for cultivators to maximize the electric efficiency of vertical indoor and greenhouse facilities. The table below describes the photosynthetic photon flux density (PPFD) target ranges for different crops grown in vertical farms. The higher the PPFD target, the more light intensity is required for crop growth and development.

Light fixtures like LEDs can produce more light with less power. VHF combines indoor and greenhouse growing methods with a hybrid cultivation approach. Tiers of plant canopy are rotated closer to walls and skylights using a carousel system to get the benefits of sunlight while also using electric lighting on each level. VHF uses a mix of different lighting fixtures in their facilities and experiments with the latest LED lighting equipment and strategies.

Since its launch in 2018, the DesignLights Consortium Horticultural Qualified Products Library has grown to list over 550 laboratory-tested LED lighting products. As of February 2022, 95% have photosynthetic photon efficacy (PPE) of 2.95 J/mol or higher.

The main takeaway? Resource efficiency is key.

PowerScore is RII’s specialized resource benchmarking platform for controlled environment agriculture production facilities. PowerScore generates KPIs for resource efficiency and productivity of energy, water, emissions and waste. The PowerScore platform accepts facility information in a variety of ways.

What's ahead

In May, RII will release best practices guides for producers and their project teams funded by the USDA. In May and June, RII and members of the Working Groups will share highlights from the guides at live workshops which will also be available for streaming on-demand on RII’s catalog.

Consider benchmarking your greenhouse operation’s key performance indicators with PowerScore at ResourceInnovation.org/PowerScore. Dig deeper by joining RII and participating in our Technical Advisory Council Working Groups; learn more at ResourceInnovation.org/TAC.